Description

Suitable for: All hive types – the gas-powered oxalic acid sublimator is suitable for use in every hive. (No special frame dimensions required.)

According to research, the gas-powered oxalic acid sublimator offers efficiency comparable to an electric oxalic acid vaporizer.

Ensure fast and efficient sublimation of oxalic acid

The gas-powered oxalic acid sublimator for sublimation of oxalic acid significantly simplifies working with your hives.

It lets you sublimate oxalic acid quickly, efficiently and easily, while remaining practical and safe to use.

Gas-powered oxalic acid sublimator developed by experienced beekeepers

The gas-powered oxalic acid sublimator is the work of experienced beekeepers who invested a great deal of effort, knowledge and practical experience into the final product.

Because they know the needs of beekeepers from hands-on practice, they created a device that best helps in real-world beekeeping work.

Make your work easier and much faster

Maintaining a colony can be demanding and time-consuming, and Varroa control is a task most beekeepers would rather get over with quickly.

The gas-powered oxalic acid sublimator allows you to perform this task in an incredibly fast and extremely simple way.

Gas-powered oxalic acid sublimator — temperature control

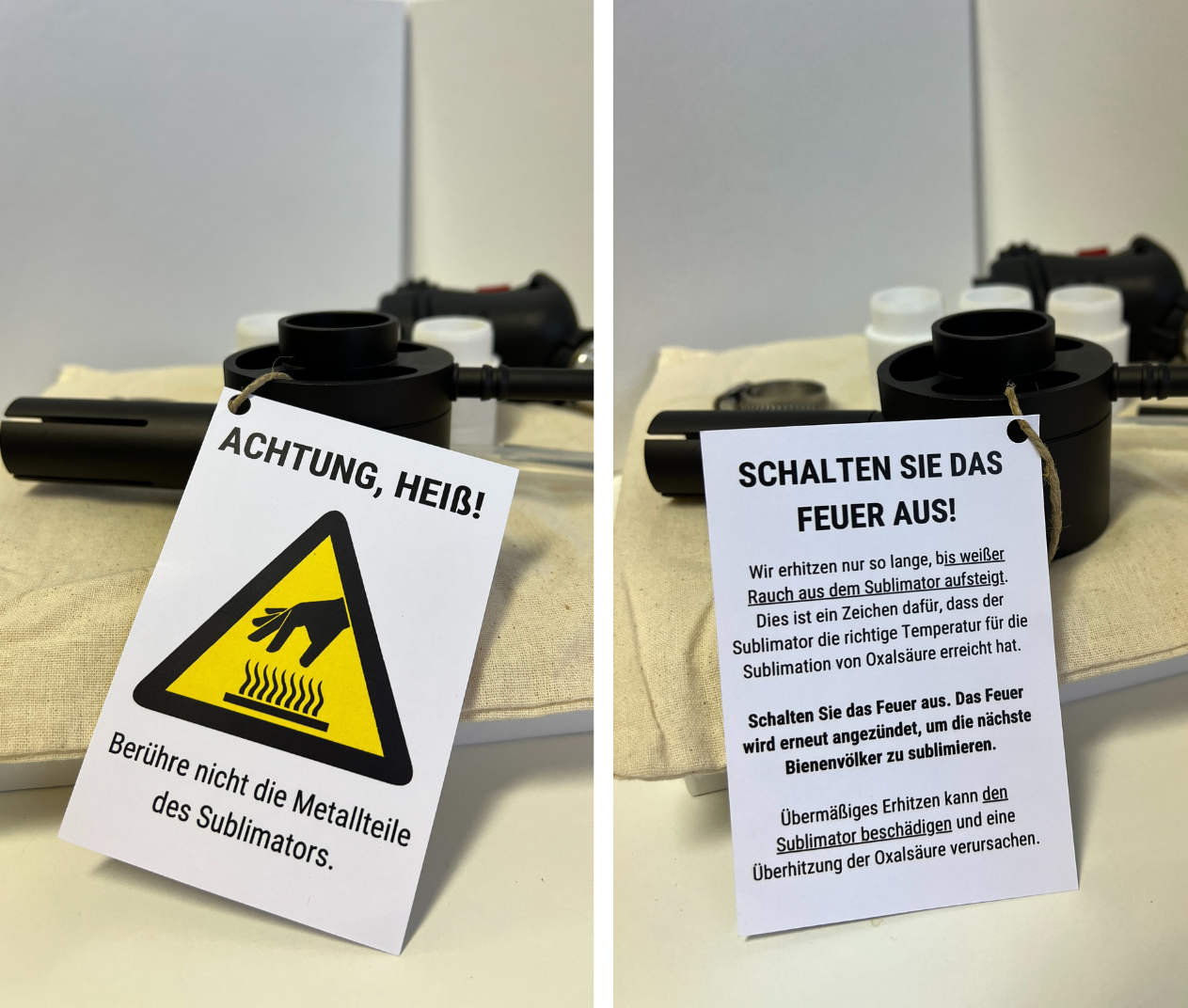

Our gas-powered oxalic acid sublimator does not have an integrated temperature controller, but with the correct procedure the temperature can be controlled easily and precisely. Simply follow the steps below to achieve optimal sublimation results:

- Flame setting: Use a low flame that provides safe and even heating.

- Heating: Heat the sublimator until white vapor appears. This indicates the ideal temperature for sublimation has been reached.

- Extinguish the flame: Put out the flame as soon as vapor appears. This prevents overheating of the oxalic acid and protects the device from damage.

- Application at the hive: Insert the sublimator into the hive entrance and wait until the vapor emission stops. The device remains hot enough to complete sublimation without further intervention.

- Repeat: For the next colony, fit a new cap with the required dose of oxalic acid. Relight the flame and heat the sublimator until vapor appears again, then extinguish the flame.

Our sublimator was tested by the Faculty of Mechanical Engineering in Maribor, Slovenia. The comparison between our gas model and an electric device with temperature control showed both systems deliver similar results with no significant differences.

Want to monitor the temperature inside the sublimation chamber?

Use the Teflon dosing cap with integrated thermometer. Available as optional accessory.

Discover the many advantages of a gas-powered oxalic acid sublimator

Completely power-free operation

The gas-powered oxalic acid sublimator requires no electricity for operation, making it an excellent choice for sublimation in locations without mains power.

Easy connection to a gas burner

The sublimator only needs a gas burner to operate, so you won't be hindered by cumbersome cables, long extension cords or heavy batteries while working.

Quick start-up

The gas-powered sublimator is ready for use almost immediately, so you can address Varroa control by oxalic acid sublimation in no time.

One device for all your needs

The gas-powered sublimator is suitable for all hive types, so you only need one device to treat Varroa with oxalic acid.

All necessary equipment included

The sublimator comes with three dosing caps for continuous work, plus a dosing spoon that ensures safe and accurate dosing.

Flexible hose for easy sublimation

The unit includes an additional flexible hose for even easier and more precise sublimation of oxalic acid.

Learn all the benefits of the gas-powered oxalic acid sublimator

Our gas-powered sublimator is thoughtfully designed and manufactured, offering beekeepers many practical advantages.

A product tailored to beekeepers' needs

The gas sublimator was developed by experienced beekeepers who relied heavily on their practical experience during production. It is optimally adapted to beekeepers' needs, easing their work and saving significant time.

Three dosing caps for continuous work

The three included dosing caps allow you to continue sublimation without waiting or risking burns. One cap can be used for sublimation while a second is being filled with oxalic acid and the third cools and is ready for the next use.

Scoop for simple and precise dosing

Accurate dosing is essential when sublimating oxalic acid. The supplied scoop lets you measure the correct amount simply and safely. It can also be used to clean the discharge tube.

Flexible hose for easier access to the hive entrance

The flexible hose supplied with the gas sublimator provides easy access to the hive entrance, allowing you to sublimate more easily, quickly and precisely.

Careful, precise manufacturing for excellent quality and reliable performance

The gas sublimator is produced from quality materials using modern technology, delivering exceptional durability and trouble-free operation.

Advanced and precise design and manufacture

The gas sublimator was designed using advanced 3D CAD tools and manufactured on highly accurate CNC machinery.

Carefully selected materials

The sublimator body is made of durable, lightweight aluminium, and the anodized surface improves resistance to acids and high temperatures.

Color change of the sublimator

The gas sublimator is made of anodized aluminium in black. Anodizing converts the outer aluminium layer into an oxide layer that provides excellent protection against corrosion, wear and acids. The surface will not melt when heated and does not release odors as conventional paints might at high temperatures. During use the color of the sublimator may change from black to brown–gold. This is expected and does not indicate any device fault.

.jpg)

Great performance with a Kemper gas burner

Great performance with a Kemper gas burner

The gas-powered oxalic acid sublimator is suitable for use with burners that have a nozzle diameter of 21.2 mm.

It was tested with the Kemper 1060 gas burner, which offers:

- Piezo ignition system for safe and convenient lighting

- Ergonomically shaped handle for comfortable operation during sublimation

- A nozzle to regulate air intake and thus flame intensity

We recommend using the gas sublimator together with the Kemper 1060 gas burner.

The sublimator is also compatible with other gas burners, provided they have the correct nozzle diameter (21.2 mm).

Replacement cartridges are easy to obtain

The gas burner uses threaded gas cartridges, which provide a simple and secure attachment of the burner head to the cartridge.

The cartridges contain a butane/propane mix so the burner will operate at lower outdoor temperatures. Replacement cartridges are widely available from hardware stores (e.g. Bauhaus, Obi) and can also be ordered from our website for direct delivery.

Order your gas-powered oxalic acid sublimator today and enjoy the benefits it provides.

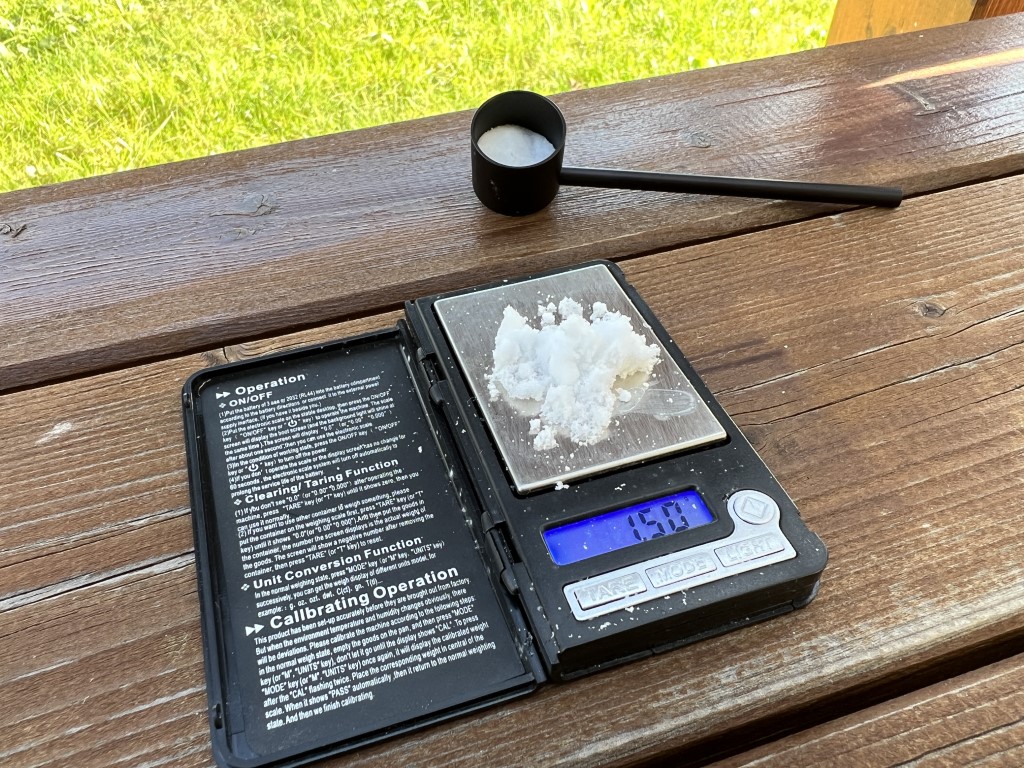

Dosing oxalic acid

The recommended amount is 1–2 g of oxalic acid per bee colony, depending on the recommendation of your veterinarian or an experienced beekeeper.

The sublimator set includes a dosing spoon. About 1/3 of the spoon corresponds to approximately 1.5 g of oxalic acid.

Pour the measured powder into the supplied caps and you are ready to start sublimation.

For simpler dosing you can also use oxalic acid tablets.

Instructions for use

The gas-powered oxalic acid sublimator is practical and very easy to operate. For an easier start we have prepared a short guide.

- First, screw the gas burner onto the gas cartridge, then place the sublimator on the burner and secure it with the supplied clamp.

- Preparation of the oxalic acid: Use the supplied scoop to measure approximately 1–2 g of oxalic acid into each cap.

- Now turn the device to the side and fit a cap with oxalic acid into position. The oxalic acid is still in the cold cap and has not yet sublimated.

- Turn the device back to its operating position so the oxalic acid powder falls into the sublimation chamber. If the sublimator is already heated, sublimation will begin immediately and white vapor will be emitted.

- Insert the gas sublimator into the hive entrance so the vapour of sublimated oxalic acid can penetrate the hive. The sublimation process takes about 30–45 seconds.

Safety warning

It is important that you only light the gas burner flame briefly — just long enough for the central chamber of the sublimator to heat up and sublimation to begin. This is when white vapor starts to appear from the device. Then extinguish the flame. This reduces gas consumption and prevents overheating of the oxalic acid or damage to the sublimator.

Use the lowest flame power that still provides sufficient combustion. To keep the flame temperature as low as possible, the burner air intake openings should be as closed as feasible.

The gas sublimator is made of aluminium, whose melting point is lower than the maximum flame temperature the burner can produce. Prolonged heating of the sublimator for several minutes at maximum flame can cause irreparable damage. Therefore, extinguish the flame as soon as it is no longer needed.

Caution! Hot!

The gas sublimator becomes very hot during operation. Do not touch it without appropriate heat-resistant gloves!

Protective equipment

Always use suitable respiratory protection during sublimation!

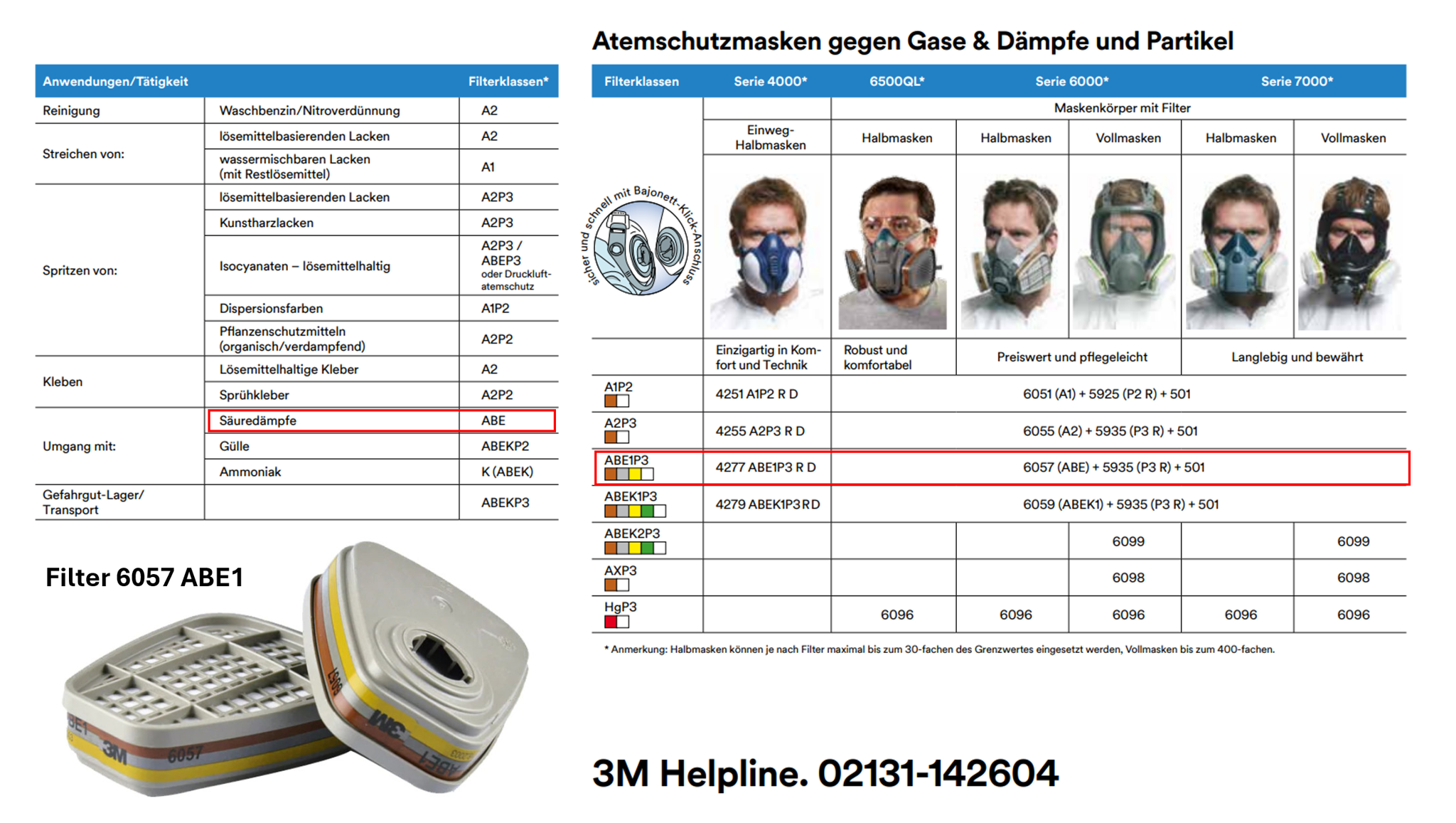

How to choose the correct 3M filter for work with oxalic acid fumes

When working with oxalic acid fumes, choosing the correct protective equipment is crucial. 3M offers a range of filters that protect against hazardous fumes. For oxalic acid vapours it is particularly important to select the correct filter class (ABE).

What does the ABE classification mean?

The ABE filter class protects against:

- Organic vapours (A)

- Inorganic gases (B)

- Acid gases (E)

These properties make ABE filters ideal for protection from oxalic acid fumes. Look for the typical colour coding in brown, grey and yellow which indicates suitability for the ABE class.

Why choose 3M filters?

3M is a proven brand known for high-quality personal protective equipment (PPE). To ensure maximum safety always buy genuine 3M filters and masks. Counterfeit products may not provide adequate protection and could endanger your health.

Recommended masks for ABE filters

- 3M half masks, lightweight and suitable for most applications.

- 3M full-face masks, providing additional eye protection and full sealing for higher-risk environments.

Both mask types are compatible with 3M ABE filters and offer maximum comfort and protection.

Important tips for selection

- Check the colour coding: Ensure your filter is marked in brown, grey and yellow to guarantee ABE protection.

- Ensure compatibility: The filter must fit securely to your 3M mask model.

- Replace filters regularly: Follow the manufacturer’s recommendations to ensure continuous reliable protection.

With official 3M ABE filters and masks you will be reliably protected from oxalic acid fumes and meet applicable safety standards. Always choose genuine 3M products to protect your health and ensure best performance.

Stay safe and work responsibly!

The official 3M PDF selection guide for choosing the right respiratory protection: 3M Auswahlhilfe Poster_In 3 Schritten zum richtigen Atemschutz_AS-0007_2015 (1).pdf

Our beekeeper friends

Technical details

- Type: Gas-powered oxalic acid sublimator (Art. No.: GS1)

- Material: Anodized aluminium, black

- Suitable for: All hive types

- Includes: 3 dosing caps, 1 dosing spoon, 1 flexible hose, fastening clamp

- Operation: Gas-powered (no electricity required); suitable for gas burners with 21.2 mm nozzle diameter

- Recommended burner: Kemper 1060 (tested)

- Dosing recommendation: Approx. 1–2 g oxalic acid per colony (approx. 1/3 of the scoop ≈ 1.5 g)

- Handling / temperature control: Control temperature by flame strength and vapor production; light the flame only briefly to heat up

- Safety: Use appropriate gloves and respiratory protection (3M ABE filter recommended)

.JPG)

.JPG)

.JPG)

.JPG)

Herr Jasper

Herr Jasper

.jpg?height=400)